Climate change is significantly impacting society and will continue to do so owing to greenhouse gases emitted, since the start of the Industrial Revolution. The extent of future climate change will depend on our ability to limit further emissions of greenhouse gases. The release of carbon dioxide (CO2) and other greenhouse gases into the atmosphere through human activities such as the burning of fossil fuels, emissions from chemical processes, and other sources of anthropogenic greenhouse gases, will have an effect on future global climate.

PAS 2050:2011 Specification for the assessment of the life cycle greenhouse gas emissions of goods and services was referenced in a recent blog by Bruce Harper on SMEs – the Road to Net-Zero. and is available from the British Standards Institute (BSI) as a free download.

PAS 2050:2011 (PAS stands for Publicly Available Specification) was first published in 2008 by BS. PAS 2050 was developed in response to a desire for a consistent method for assessing the life cycle GHG emissions of goods and services. Life cycle GHG emissions are the emissions that are released as part of the process of creating, modifying, transporting, storing, using, providing, recycling, or disposing of such goods and services.

What exactly is PAS 2050 and how can it be used?

PAS 2050:2011 provides a comprehensive and consistent framework for carbon footprinting of goods and services that can be applied to any product or service.

The 2011 revision makes the PAS 2050 methodology more relevant and accessible to a wider range of businesses by drawing on the experiences of users since the standard’s publication in 2008. Some of the significant changes arising from the review are as follows:

- provision for the development and application of ‘supplementary requirements’ to enable more specific greenhouse gas emissions assessment within sectors or product groups

- the inclusion of emissions from biogenic sources (e.g., biomass)

- greater clarity on the treatment of recyclable material

The GHG emissions associated with goods and services reflect the impact of processes, materials, and decisions occurring throughout the life cycle of those goods and services.

The primary objective of this PAS is to provide a common basis for GHG emission quantification that will inform and enable meaningful GHG emission reduction programmes. Product/service carbon footprinting should be used as a practical tool that is tailored to the needs of your organisation. It can be used to identify the main sources of emissions for all types of goods and services. Consideration of the goal/objectives of a carbon footprint study is of paramount importance, to ensure that it will deliver the information that you need.

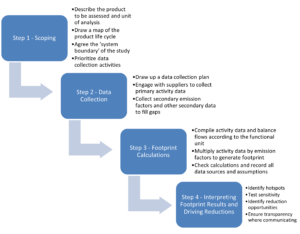

A footprinting project should always be broken into a series of steps. These are sequential and cannot be carried out in isolation. The steps detailed below are based on a guidance document produced by BSI and the UK government departments DEFRA/DECC/BIS.

Step 1: Scoping

Scoping is the most important step when undertaking any product carbon footprint study. It ensures that the right amount of effort is spent in getting the right data to achieve meaningful results in the most efficient manner possible.

There are four main stages to scoping, and they are best undertaken sequentially.

1.1. Describe the product to be assessed and the unit of analysis

It is vital that the product to be assessed is clearly defined at the outset. For its carbon footprint, the product must be defined in terms of a ‘functional unit’. The functional unit defines the function of the product that will be assessed and the quantity of product to which all of the data collected, will relate.

1.2. Draw a map of the product life cycle

Once the functional unit has been defined, the next step is to map out the life cycle of the product to be assessed. Map all of the ‘flows’ of materials and energy in and out of the product system as they are used to make and distribute the product.

1.3. Agree and record the system boundary of the study

Once the process map is complete, it can be used to identify which parts of the overall system will, and will not, be included in the assessment.

As an output from this scoping stage, you should clearly document and record the system boundary in terms of:

- a list of all included life cycle stages (e.g., raw materials, production, use, end-of-life)

- a list of all included activities and processes within each life cycle stage

- a list of all excluded activities and processes, and the steps taken to determine their exclusion.

1.4. Prioritise data collection activities

Having defined a system boundary, the next step in the scoping stage is to prioritise data collection activities. Data collection is commonly the most time and resource intensive step in any carbon footprint assessment. Therefore, prioritising the data that are needed is a hugely important.

Efforts and priorities should also be linked to the intended purpose of the study.

Step 2: Data Collection

2.1. Draw up a data collection plan

Having prioritised data needs during scoping, it is good practice to develop a data collection plan, to focus efforts and provide a reference to draw on.

2.2. Engage with suppliers to collect primary activity data

Engaging suppliers in the carbon footprint process will help you to collect specific primary data for your supply chain, giving greater insight into emissions sources.

2.3. Collect and use secondary data

Secondary data are typically used in footprinting studies as a source of:

- emission factors – which convert primary activity data (material/energy/process inputs and outputs) into GHG emissions (in kg CO2e)

- information to fill gaps in primary activity data

- information to calculate the impact of ‘downstream’ life cycle stages e.g., use and end-of-life (you do not need primary data for these stages)

2.4. Collect data for ‘downstream’ activities

‘Downstream’ activities refer to processes that occur during product distribution, retail, use and end-of-life. Of these, you typically only need to collect primary activity data for distribution (unless retail is part of your business activities). However, the use phase can be the most important life cycle stage for products that need energy for operation, require cooking, etc.

2.5. Assess and record data quality

The accuracy or quality of your product carbon footprint is ultimately dependent on the quality of the data used to calculate it. It is critical that you consider the quality of the primary and secondary data you have used and demonstrate that they accurately represent the footprinted product.

Step 3: Footprint calculations

3.1. General calculation process

A useful first step in the calculation process is to map all of the ‘flows’ occurring and calculate the quantities associated with each flow. Having already developed a process map in Step 1.2, it can be used to map out all of the inputs, outputs, distances, and other useful ‘activity’ data for each process stage.

3.2. Calculations for specific aspects of the footprint

PAS 2050:2011 now contains a number of revised clauses with regard to the accounting procedures for inter alia, biogenic carbon accounting and carbon storage, CHP, grid electricity, agriculture, land use change, refrigeration, storage emissions, recycling and landfill and incineration.

Step 4: Interpreting footprint results and driving reductions

The most important step of a PAS 2050 assessment is interpreting carbon footprint results and identifying carbon reduction opportunities. Results of the assessment provide valuable information that can be used to understand and manage the GHG emissions associated with the assessed product and, more widely, at an organisational level.

4.1. Understanding carbon footprint results

The output from footprint calculations will be a ‘total’ footprint value for the agreed functional unit. This will be broken down according to the contributions for each material, process and life cycle stage.

This is powerful information, showing the emissions hotspots across the life cycle. Through breaking down results in a variety of ways, the materials, processes or life cycle stage of most concern can be identified to allow for a targeted reduction strategy.

4.2. How certain can I be about the footprint and hotspots?

A PAS 2050 product carbon footprint can only be regarded as an estimate. Inevitably, there will be inaccuracies in standard emission factors used, data collected, knowledge gaps filled by assumptions and global warming potentials used. This is not necessarily a problem, providing it is known what purposes the carbon footprint can and cannot be used for.

4.3. Recording the footprint

Annex B of PAS 2050 provides requirements for the recording of supporting information, which should be followed.

4.4. How can I use footprinting to drive reductions?

Carbon footprinting can be a basis for reducing carbon emissions and energy use, while also conveying a positive message to different stakeholder groups.

Through the interpretation of the carbon footprint of your product or service, it should be evident which areas of the life cycle, which materials and which processes should be targeted for reduction.

Antaris, in conjunction with the Enterprise Ireland Climate Enterprise Action Fund, is now a service provider for a range of green, environmental services under three programme initiatives – GreenStart, GreenPlus and Climate Action Voucher, helping Irish companies compete and grow global investment as a greener future accelerates, as well as comply with regulations and build a more credible profile. Therefore, we are in a position to advise you on your assessment of the life cycle greenhouse gas emissions of your products and services. You can read more about these services here.